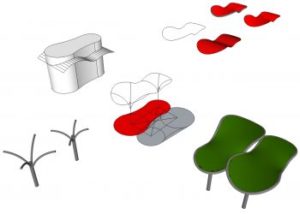

More often than not, tensile architecture often requires a design strategy involving a wide variety of shapes, materials, and tensioning decisions. Offering design assist services working with architects and owners, Eide Industries’ preliminary design and rendering capabilities will help bring your tensioned fabric structure to life.

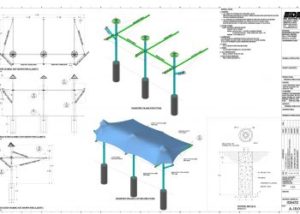

It all starts with your idea, plan or concept. With your imagination and TECHNOSPAN expertise, we will work together to configure the most efficient and economical design using only high-quality tensile membranes that offer grace, beauty, strength, and functionality. Challenging to envision in two-dimensional views, TECHNOSPAN rendering capabilities showcases proposed concepts in 3D from any desired angle to answer, enlighten, identify and/or resolve any issues.

Whether it’s a permanent durable PVC /PTFE membrane canopy or deployable flexible PVC fabric structure, Tension Structures by TECHNOSPAN will help you discover new solutions to conventional design challenges.

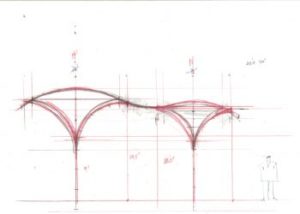

Once a functional and feasible design concept has been developed, engineering of the tension fabric structure can begin. TECHNOSPAN engineering services include everything required to certify our tensile structures with permitting authorities for stress, wind, snow and/or seismic activities.

These services include:

- Structural Design Calculation determine reaction forces of the structure under simulated loads such as the wind, gravity, and pretension of fabric and cables.

- Engineering calculations to ensure the structure is suitable for the loads in your city or region, whether it’s 145 Kmh West coat of India, 210 Kmh Cyclone or hurricanes winds in eastern cost of India or similar in any parts our business regions in overseas.

- Support Reaction forces to check the stability of buildings Or to design suitable foundations as per the load bearing capacity of the area where the structure id going to install.

- Optimization of frame structure member sizing and anchoring.

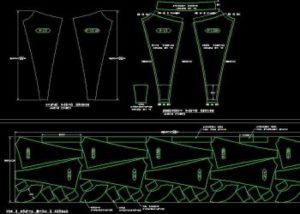

- Precise fabric patterning of the tension structure membranes to ensure a tight and wrinkle free fit.

- Engineering drawings and calculations suitable for local permitting authorities.

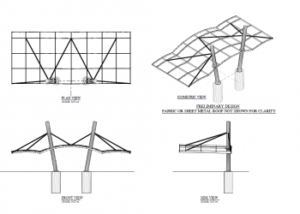

- Detailed and approved shop drawings and work shop drawing for manufacturing.

- As build drawings after the execution of the work.

- Maintenance manual for period maintenance for the long lasting and durability of the structures.

After final engineering is completed, manufacturing and fabrication of the membrane and structural steel begins. During the fabrication phase, prestress PVC or PTFE fabric membrane is cut and welded to create final panel sizes to be installed in the field. Once the manufacturing of the membrane and steel members are finished, packaging of the materials are carefully handled for shipping and unpacking at the job site.

Operating from a 3000 square meter manufacturing facility with over 20 years of experience, there are virtually no limitations to the size and complexity of tensile structures that we can build. TECHNOSPAN is an Certified and accredited Fabricator with most of fabric manufacturing companies with the ability to construct nearly any conceivable tensioned fabric structure.

30 m long 20 KW HF (High Frequency) travelling machines 3-4 stationery and HF Heat Sealing Machines to weld PVC (Polyvinyl Chloride) and other high-frequency textile fabrics. Swedish made.

The construction phase of tensile systems is a critical element to the overall success of a project. Our installation department is certified to construct the most elaborate tensioned fabric structures and help build your dream into a reality. As a design-build specialty contractor, TECHNOSPAN dedicates long hours of planning and attention to detail creating an installation procedure utilizing necessary equipment and manpower for each custom PVC or PTFE OR ETFE projects.

Typical equipment that may be operated to assist in tension structure installations includes Cranes, Construction Forklifts, Booms lifts, and Scissor Lifts.